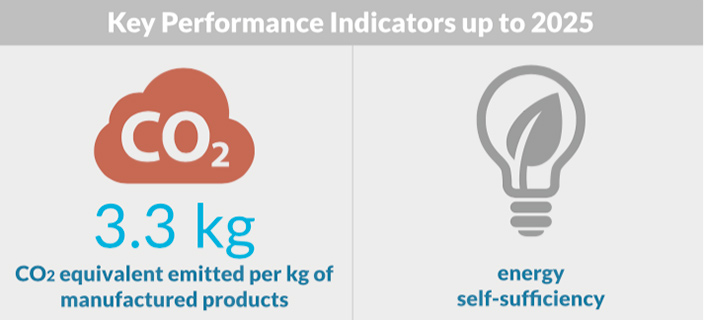

Measuring our environmental impact

French Polynesia has not been spared by climate change and its multiple manifestations. To implement an environmental sustainability strategy, we measured the environmental impact of our organization. Our first greenhouse gas (GHG) assessment was finalized using the methods of Bilan Carbone® (the carbon accounting system of Association Bilan Carbone) in 2014. This study was carried out on the basis of data from the 2012 fiscal year and made it possible to determine the most significant sources of greenhouse gas emissions. After this analysis, targeted and company-specific reduction measures were proposed and implemented. Given that the frequency of the GHG assessment has been set at three years, the last one was performed in 2015. The biggest sources of emissions are still inputs and freight. “Inputs” consist of the materials and equipment, services, and current and annual purchases necessary for company operations, while “freight” corresponds to the merchandise, equipment, tools and company supplies transported by sea, road or air, and raw materials not factored into “inputs.” By 2025, by means of reducing its energy consumption and complying with sustainable purchasing, LCPS commits to reducing the carbon footprint of its products by 10% and applying this measuring method at its production site in the South of France. With approximately eight hours of daily sunshine, photovoltaic solar energy carries enormous potential for the Polynesian islands as an alternative energy solution. We are planning to reduce our energy consumption by 70% by installing solar panels and using a biofuel instead of the fossil fuel used to power certain equipment.

Managing effluent and waste